Manufacturing

Manufacturing

with Secure & Easy Remote Management

Applications

Critical Manufacturing

Production process remote Time Synchorization

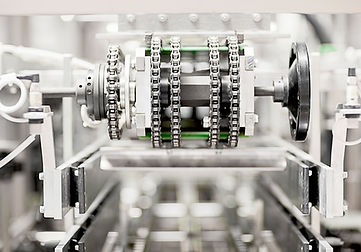

The Critical Manufacturing are complicated, not only variety control protocols systems or devices for manufacturing process, but the most challenge is the precise of any product process status data, which is required to have the same data timestamp synchronized with local or remote time servers, in order to discover any production error which any impact affect the quality of products.

Besides the mixed protocols conversion gateways would support customers to interconnect those various control protocol equipment for data exchange and communication with backend SCADA, an industrial Ethernet Managed Switch will play an important key factor to ensure network uptime, data transmission for any equipment.

The industrial Ethernet Switches should feature the latest Layer 2 data/network function, fast network recovery protocol to obtain network uptime, industrial-grade to withstand the extreme temperature, high emission, and shock/vibration environment; plus the most important is to support the hardware-based Precision Time Protocol (PTP) followed by IEEE1588v2 standard and having function setting for both boundary and transparent clock, in order to to obtain the data accuracy.

-

Front-end computing – Fan-less high I/O density embedded computer features predictive maintenance capability to ensure high longevity for flexible data acquisition

-

Network Redundancy – Fast network recovery <50ms support 24/7 network uptime

-

System network security – Industrial secure routers with All-in-1 security protection function to prevent any unauthorized access

-

Variety protocol communication – Multiple protocol gateway connect the all devices on the production line seamlessly

. Recommended Products

Product Line Management

The modern production line management system facilitates the need of remote monitoring that allows supervisors to see what is happening on a factory floor whether the lines are running slowly or stopped. Implementing such an operation requires a reliable and smart device networks to transmit data back and forth between the control center and devices in real time, and to ensure that automated systems run seamlessly via both wired and wireless networks.

2RL Communications delivers the diverse field network communication for multiprotocol connectivity solution products to allow clients to efficiently integrating all those equipment under same system network. All communication solution products features self-healing network solution to ensure non-stop communications; plus highly secure Ethernet connectivity solution to safeguard remote SCADA management.

Solutions

Providing industrial-grade solution products, including Industrial Ethernet Switches, Secure Routers, Devices Servers, Ethernet I/O Gateways, industrial network management software suite, and Embedded Computers, which are designed and developed with

-

Support wide operating temperature up to -40 to 75 degree C

-

Intuitive remote configuration feature for easy maintenance and remote troubleshooting

. Recommended Products

Equipment Manufacturing

Equipment manufacturing rely on standalone control process systems and utilizes different industrial control systems with variety legacy control protocols for the production process.

2RL Communications understanding customers’ challenging and delivers the best fit communication and networking products with diverse protocols, interfaces, and media solutions to interconnect communication or data exchange among the legacy and advanced control protocols and systems to improve productivity and operational efficiency.

Our industry expert team will also offers our customers’ upfront applications discussion and identify the right solution products with the engineer-friendly interfaces for easy device installation, operation, and maintenance; in order to assist customers to have the best ROI with time & cost, and real-time remote production monitoring and secure remote management.

Solutions

-

Interconnection – Diverse control protocols, interfaces, and media Ethernet Gateways to connect the unconnected equipment

-

Front-end Computing – Palm-size computer with wireless connectivity with ready-to-run Modbus for remote supervisory

-

Network connectivity – To extend Ethernet-based devices connectivity with Compact, slim size industrial Ethernet Unmanaged Switch, or lite-layer 2 managed function and easy industrial control protocol network integration, such as Ethernet/IP, PROFINET, and ModbusTCP

-

IP Scheme setting – Utilize Network Address Translation (NAT) functions to eliminate complicated network settings and deployment efficiency

-

Security – Implement Firewall policies for control network traffic, in order to shield the internal machine network and prevent any unauthorized activity by outside host

-

Sure and Remote Management – Using industrial network management software suite for network installation, operation, maintenance, and diagnostics stages for the entire machine network’s life cycle